Basically hammers as they come from the store are not quite ready for blacksmithing.

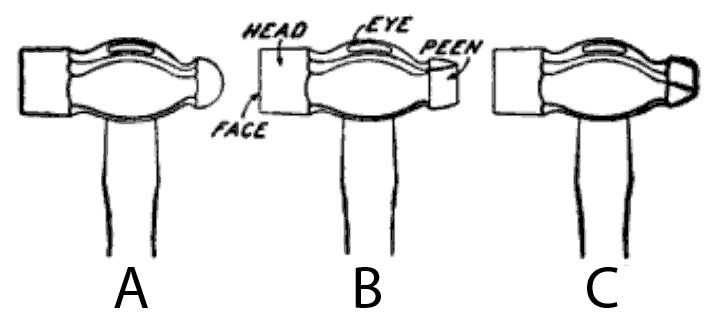

Before we can talk about it here are the parts of the hammer.

New hammers have a bevel around the rim with a sharp edge. You can see it on this cross peen hammer

If you don't remove this, if you hammer even slightly crooked it'll leave marks all over your metal

Here is a pic of a hammer just slightly softened.. which helps to prevent marks (though I suggest more sanding) You can still see the bevel, but the line separating it from the face is softened.

When you have this rounder shape you can tilt the hammer to various angles to do slightly different operations(2 way stretch or1 way stretch, etc).

Here is one much more softened but needing a bit of polishing (any marks on the hammer face are transferred to your work like stamps)

Lots of folks like different shapes...

Here is a much more in depth article (though it lacks pictures) on the subject

anvilfire.com

another good one

Video

Here you can see the peen of a hammer has sharp edges from the factory too.

You'll want to do the same to the back or Peen side of you hammers, to prevent them marking the steel as you work too.

Now your hammer is ready to polish as much as you care to (more is better within limits)

Then Bang on hot iron and make cool stuff.

No comments:

Post a Comment