In it's essence, you need fire, Steel(iron) something to hit it on and something to hit it with.

2 rocks will honestly work better than you might think... But that's not the kind of answer you're looking for...

A Starter Set

Centaur Forge sells a Starter kits that's pretty good.

You can get it Here, but what if you need to do it on the cheap... that's what this blog is partially about. First off skip the DVD and the Block of bees wax in the picture.

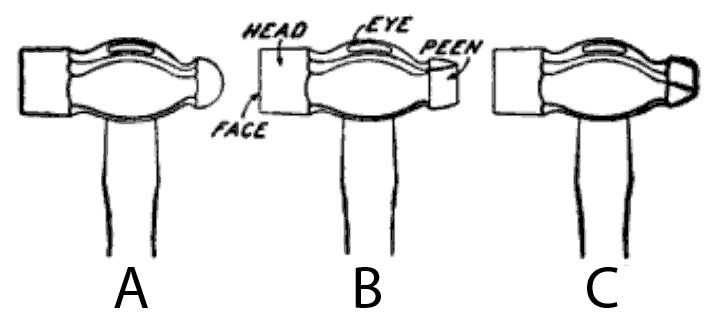

You need A decent hammer. a straight or cross peen will work great after you

Dress the face.

Here is a cheap one from harbor freight. Not great, the steel is ok but the heat treat is meh. it'll work great to get you started.

3 lb cross peen hammer it's a bit heavy to start out with so if you can find a 2lb one that's better. If not, just choke up on the grip towards the head till you start to get some control. Let the weight of the hammer do the work, you just guide it as it falls.

Eye and or Ear protection... for coal or similar, any regular shop stuff will do... For propane forging you need special ones that block both the UV light and the IR light.. or it'll jack up your eyes.

before you get them, you can't really look into the forge safely for more than a bit. think sunburn on the inside of your eyes...

Gloves, and a leather apron, are optional but good ideas, you can get these at harbor freight too..

You need some kind of wire brush to remove forge scale...anytime will work as long as the wires are steel and will not melt out of the brush ...

This is the cheapest I've found (again harbor freight)

Steel wire brush

Next you need something to cut metal with... anything will do, but if you have access to electricity I suggest a angle grinder with a asst. of disks for cutting sanding and Grinding.. for $25+ for a set, it's just too good a deal... be super careful though and use hand eye and ear proptection, because Grinders love to feast on human flesh... be warned, and don't get lazy or stupid. Look in my other posts for more detail.

With this and a long piece of metal and or a cheap as pair of pliers of vice grips (or even better one of the easy tongs I show how to make in other posts) you are upto the minimum levels.

If you can't afford that, get a cheap hacksaw and the best hacksaw blades you can afford.

Also extremely handy is something to hold water as a quench tub, to cool off the steel. Plastic will work for a while, just be careful not to let hot stuff touch the sides or bottom...

If you are using a coal fire, I suggest at you make a fire rake and then rivet a tin can onto a handle and make a ladle for your quench bucket.

like this:

Though to be honest I prefer one make just like the fire rake,and the flat bent part of the rake is bent to fit the can, and then riveted (or bolted) on... I can't find a good pic at the moment so kind of like this:

no matter the fire make at least 2 pairs of BSA Ez Tongs before you go any further.

You will need a vice... if you can possibly get it, any vice is better than none..

Improvise an Forge

and Find something to use as an anvil

and you are ready to make something fun!